FORGING THE FUTURE

It takes years of extensive and intensive experience to establish a firm footing of reliability, stability, consistency and fidelity to manufacture technically advanced industrial forgings and finished machined components year on year, without failure or setback. PYU is all about this and more.

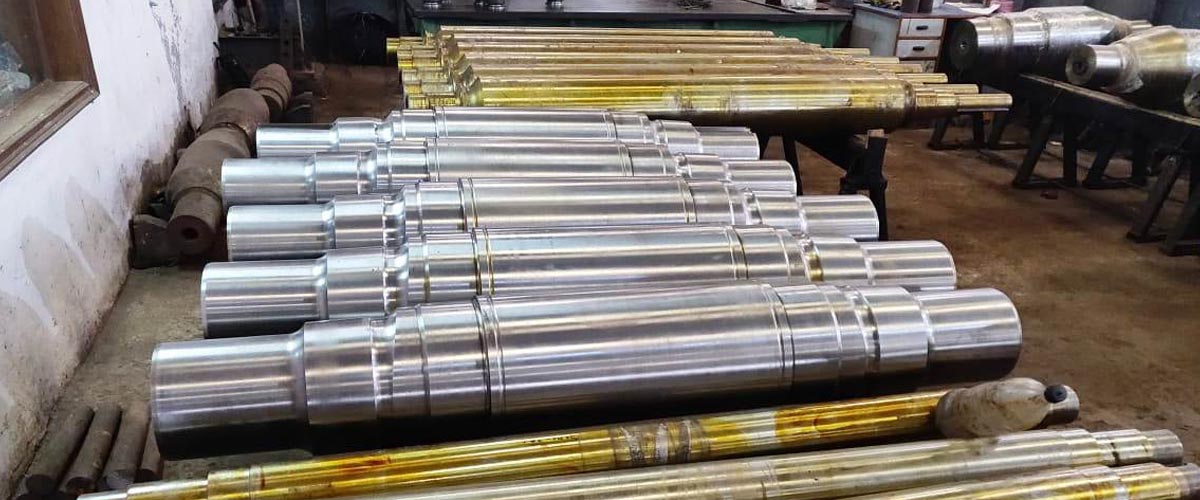

WE ARE THE LEADING MANUFACTURERS IN INDIA OF FORGED AND FINISHED MACHINED (READY TO USE) PRODUCTS.

Established in 1990, PYU grew out of humble beginnings on the outskirts of the country’s capital, Delhi. On the strength of a highly dedicated symbiotic work-force, and the continual improvements in machine, material,processand manpower, PYU gained exponential momentum, delivering products to many an esteemed Clientele. With the required quality certification of ISO 9001-2015, 14001-2015 and 45001-2018, nurturing the core values of leadership, continuous improvement and team integrity, today PYU stands stoic, confident and surging ahead under its 3rd generation of entrepreneurship, as its rich legacy.

Our Mission

Our Mission is to supply products complying to the highest quality standards and to the complete satisfaction of the Customers, by means of staunchly abiding to the process and statutory and regulatory protocols laid down for continual improvement.

Our Vision

We envisage keeping a progressive outlook by setting realistic objectives of implementing technology advancements, upgrading infrastructure and becoming independent with respect to in-house mantainence and improvements, as well as optimising resources to increase productivity and reach the highest possible position in the market.

Management Team and Policy

The Management comprises of experienced, qualified experts in respective fields as well as visionaries who not just carefully monitor the present goals but also diligently craft future plans for expansion.

A fair policy is inclusive of a growth path and opportunities for all individuals. The highly motivated and committed team has a high retention rate, which benefits the overall quality and productivity of PYU. The skilled workmen, experienced supervisors and technicians, passionate engineers and quality inspectors, highly devoted admin staff and driven sales and service executives, the managers and senior office bearers create a cohesive, conducive work environment at PYU.

Mr. R. P. Garg, Chairman

A distinguished alumina of IIT, Roorkee in the mechanical engineering stream has been a pioneer in all aspects of designing & amp; manufacturing engineering equipment, for over five decades, for the Power generating Plants (both Thermal & Hydro), Steel Plants, Cement Plants, Shipbuilding, Sugar industry, Mining, Petro-Chemicals and Material handling, etc. Being a first-generation entrepreneur, Mr. Garg is an accomplished professional proven by the fact that he has been expanding his manufacturing base to greater scales year after year right from the beginning. This has been possible owing to his great leadership qualities exhibited in every step of his professional journey.

Mr. Garg possesses a great understanding of designing & manufacturing mechanical systems and is highly experienced in product testing and development. Possessing problem-solving abilities, he has great communication quality.

Mr. Deepak Garg, Managing Director

Having experience of around three decades in the manufacturing industry, Mr. Deepak Garg is quite proficient in all aspects of manufacturing processes. Being an Engineering Graduate from a reputed institute, he possesses in-depth knowledge of design engineering, manufacturing, and operations of the engineering equipment.

Having an eye for detail, he has been all through a great team player which has enabled him to expand his business year after year and has been further accentuated by his great leadership skills. Mr. Deepak possesses great communication skills and can explain technical concepts with full clarity even to non-technical audiences.

Mr. Deepak is talented enough in the field of innovation – a subject close to his heart. He has been responsible for the accomplishment of jobs that others in the industry had declared impossible to execute. This is allowing for his clear design concepts and detailing of manufacturing processes.

Mr. Biswajit Das, CEO

Mr. Das is an accomplished engineering graduate with a post-graduation in management and having a professional experience of about 40 years in manufacturing & Technology

during his tenure at the prestigious company BHEL. He has been involved in the Development of New / Advanced processes regarding existing facilities & capabilities and also for the Development of Special Tools for the specialized manufacturing processes. He had been responsible for the Indigenization of Raw Material both for Casting as well as Forging during his long career.

Besides, he is a great Facilitator for R & D activities thereby Nurturing qualities of Innovation & Creativity among his team. He has also been responsible for transforming the organization’s culture to kick start the Process of Improvement. Being endowed with great leadership qualities, Mr. Das believes in teamwork. Mr. Das is working in Hydro Prakash Division as Senior Vice President, apart from that he also holds the post of CEO in the Forging division of Prakash Yantra Udyog Pvt. Ltd.

WHY SHOULD YOU OPT FOR PYU FORGINGS?

Each day, the global forging industry is advancing by leaps and bounds. It is estimated that the global forging market will expand at 4.4% CAGR till 2025, to reach its worth at $96433.7mn by 2025. It is a known fact that there is an increasing demand for metal forge globally. Forged parts are much preferred in high precision industries like aerospace, automotive, water circulation, refineries, manufacturing, heavy engineering, power, fire systems, and automation to name a few. When the demand is high, process applications critical, with no scope or margin for error or failure, what you need for reliable quality, precision manufacturing and consistent performance is experience, expertise and extraordinary workmanship

PYU is your one-stop shop if you are looking for a fail-proof solution for your needs.

Strong and reliable

We at PYU understand the application that the forged part will be put to use. We also understand no other metal treatment process can ensure the superior strength of forged metal parts. Moreover, since the high strength is a result of the tight grain structure of the forged metal, forged products can maintain their performance on a wider temperature range. The ductility, reliability, and strength of forged products go beyond the cast, fabricated and welded products. This is often a reason for forged products to find its application in industries in which human safety is crucial.

Better metallurgical properties

Sometimes selective heating and non-uniform cooling that take place in the machines become the main reason for wear and tear of a part due to mechanical stress and consequent failure of that particular part. However at PYU, the final product of the forging process does not have any internal voids and has superior grain flow. Every product is thoroughly inspected for quality assurance. We ensure that the forging process reduces the occurrence of shrinkage and porosity which is commonly seen in cast products. Attention is given to ensure the chances of unexpected failure under stress or temperature differences are nullified in machine forging.

Various metallurgical options available

The biggest advantage of machine forging process is that most of the metals can be forged into the desired shape. By using strong forged metals, industries can smartly curb use of expensive alloys to achieve high strength components. Some of the common forged metals are aluminium, alloy, stainless steel, brass, carbon, titanium, copper, brass, etc. Each metal comes with a distinct set of characteristics which can be used for optimised performance depending on its application. At PYU you can avail the experience and knowledge base for consultation on the forging best suited for the type of metal depending on where it is to be employed.

A cost-effective solution

It is well known that the materials used in forging are less expensive when compared with other materials, used in metalworking processes. Forging has a significant cost advantage, particularly in precision metal manufacturing in high volume production. At PYU the manufacturing process is precise owing to our state-of-the art updated machinery, experience and quality procedures; hence any product requires fewer secondary operations in most cases. As a result, the finish material is obtained with the exact dimension and good surface finish. Very low machining for further finishing, contributes to a cost-effective solution at PYU.